As a founding member of HYPOS e.V. (Hydrogen Power Storage & Solutions East Germany), VGS has been supporting the development of a model region for hydrogen use in eastern Germany since 2015. The initiative coordinates supporting research into the geo-mechanical, microbiological, and safety-related aspects of the pilot project - the underground storage of hydrogen (H2-UGS) in central Germany. VGS is an associated partner of the project, which is developing guidelines for the creation of underground hydrogen storage facilities. As part of the global flagship project, VGS is also researching materials and technology for the storage of H2 derived from renewable power at an industrial scale.

"Storage of Hydrogen in Salt Caverns – A Vision of the Future"

"Energiepark Bad Lauchstädt"

The model region in central Germany is also heavily characterized by the chemical plants and centres of Leuna, Merseburg and Bitterfeld. They have a high demand for hydrogen. Current estimates suggest that up to 1.3 billion m3 of demand can be replaced with green hydrogen by 2025. Long term plans include replacing up to 9 billion m3 by 2050. This is yet another area in which the wind farm and cavernous storage will play a central role. The solution-leached caverns are found at a depth between 765 and 925 meters within a layer of salt up to 500 meters thick.

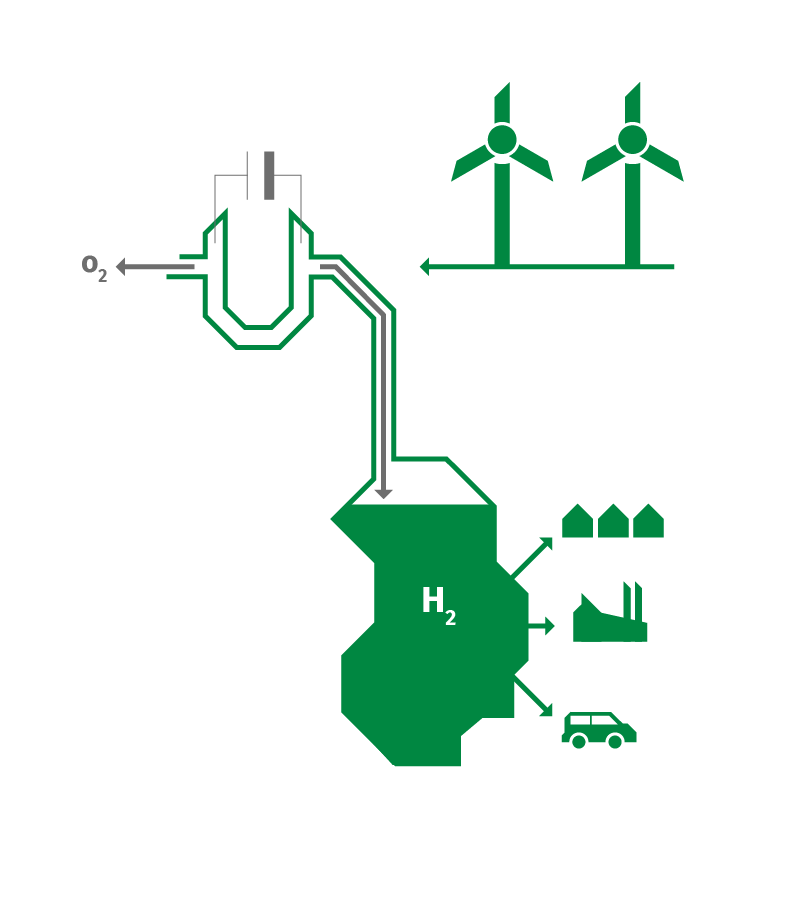

The storage platform and large-scale electrolysis will be created as part of the Bad Lauchstädt energy park. Initially, the results of the H2 cavernous storage research platform will be built upon in an operational research phase. An additional project element, a wind farm in the immediate vicinity of the Bad Lauchstadt storage facility, will be set up by a project partner. The Bad Lauchstadt energy park project is one of three partial projects which, together, make up the main Green HydroChem project. These three partial projects are all fundamentally independent yet linked by a common H2 infrastructure.

The ideal location of the caverns means that they can easily be connected to the hydrogen infrastructure already present in central Germany’s “chemical triangle” of Leuna-Schkopau and Bitterfeld.